| Availability: | |

|---|---|

| Quantity: | |

SQ10SU3

BOB-LIFT

The 10-ton telescopic boom crane is a highly efficient equipment to complete multiple lifting and construction jobs. Its proven popularity can be attributed to its versatility, ability to reach heights, and reliability in load management.

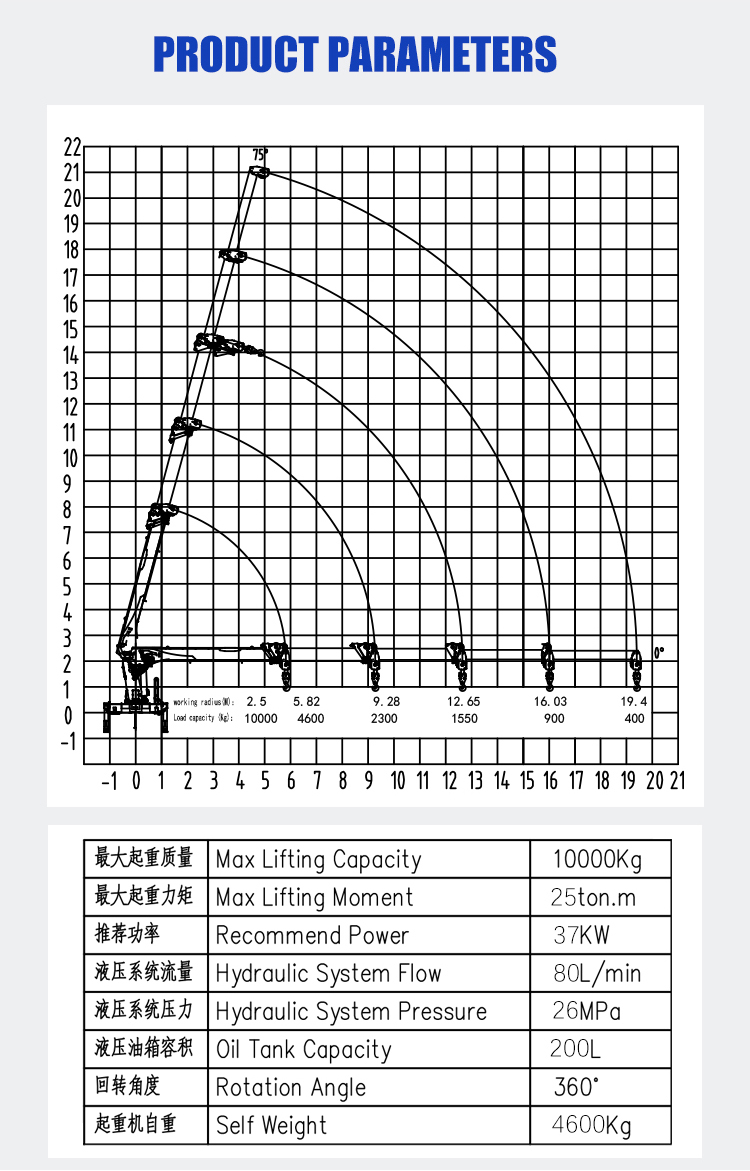

| Max Lifting Capacity | Ton | 10 |

| Max Lifting Moment | Ton.m | 25 |

| Recommend Power | KW | 30 |

| Hydraulic System Flow | L/min | 63 |

| Hydraulic System Pressure | MPa | 25 |

| Oil Tank Capacity | L | 160 |

| Installation Space | mm | 1200 |

| Self Weight | kg | 3650 |

| Rotation angle | ° | 360 Continuous |

One of the features that makes the 10-ton boom crane a best seller is its telescopic arm feature and its flexibility in extending over long rotation angles. Thanks to the crane’s unique features, operators can handle obstacles, access restricted spaces and achieve greater heights. Think of tasks like moving objects on construction sites, or trees in forestry applications whichever the use, efficiency is a guarantee.

The crane has a design that allows for mounting on trucks so you can easily access the work sites at your convenience. The mobile crane’s popularity in different industries is because of its reliability in transportation and installation.

The 10-ton telescopic boom crane is a highly efficient equipment to complete multiple lifting and construction jobs. Its proven popularity can be attributed to its versatility, ability to reach heights, and reliability in load management.

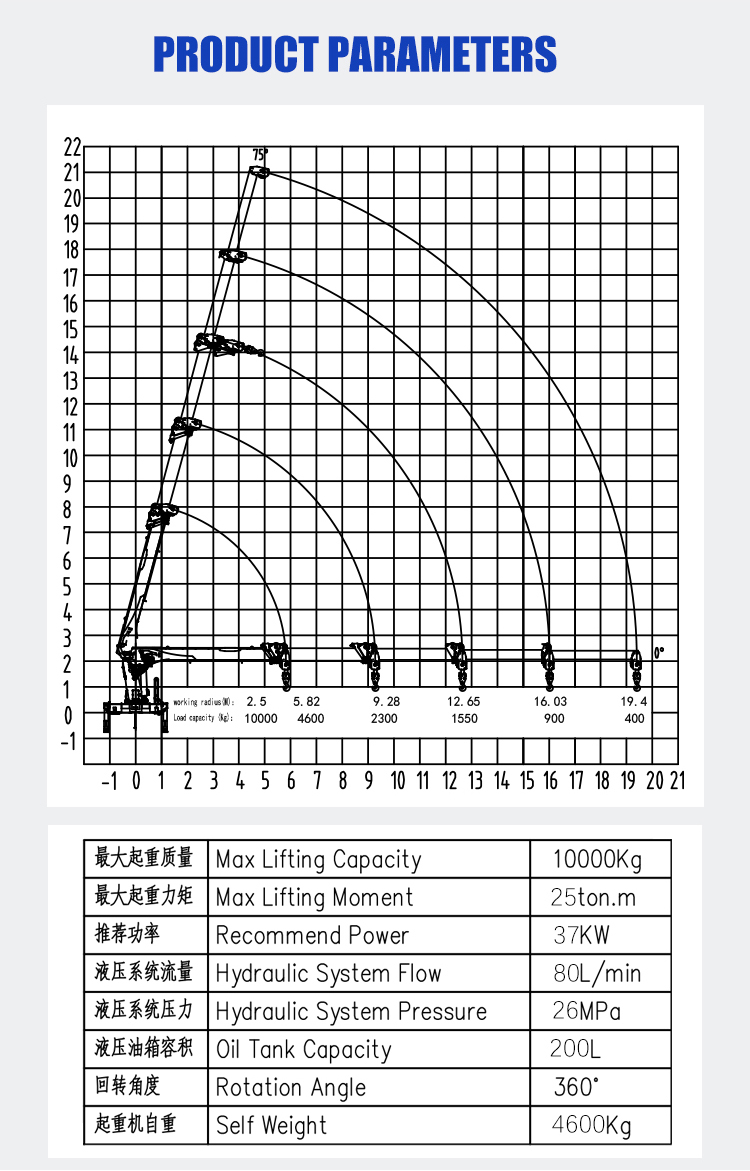

| Max Lifting Capacity | Ton | 10 |

| Max Lifting Moment | Ton.m | 25 |

| Recommend Power | KW | 30 |

| Hydraulic System Flow | L/min | 63 |

| Hydraulic System Pressure | MPa | 25 |

| Oil Tank Capacity | L | 160 |

| Installation Space | mm | 1200 |

| Self Weight | kg | 3650 |

| Rotation angle | ° | 360 Continuous |

One of the features that makes the 10-ton boom crane a best seller is its telescopic arm feature and its flexibility in extending over long rotation angles. Thanks to the crane’s unique features, operators can handle obstacles, access restricted spaces and achieve greater heights. Think of tasks like moving objects on construction sites, or trees in forestry applications whichever the use, efficiency is a guarantee.

The crane has a design that allows for mounting on trucks so you can easily access the work sites at your convenience. The mobile crane’s popularity in different industries is because of its reliability in transportation and installation.